High Performance Surface Chemistry.

Diagnostic Applications. Real Clinical Relevance.

The MCP family of copolymers have limitless potential as a surface-coating material.

An optimized reflective substrate, combined with high-performance surface chemistry, offers powerful potential uses for diagnostic applications of real clinical relevance(1)

Advantages of copoly DMA-MAPS-NAS

- Easy: coating without a chemistry lab, eco-friendly (1)

- Universal coating, works with different materials (glass, silicon oxide, plastics, gold ..)

- High probe density: more binding sites per unit area

- Hybridization efficiency: (up to 80% vs. 40-50% existing silanization), welling prevents steric hindrance (2), target can bind far from surface (3)

- Low background (3)

- Structure Retention: Gentle binding helps retain delicate protein structures (1)

- Limitless Potential: compatible with microelectronic, optoelectronic, microelectromechanical devices (1)

Why use these copolymers?

- Captured targets retain their function (3)

- High surface density of functional groups means more captured targets

- Elevated probes mean better target capture

- Low levels of nonspecific binding: better data analysis

Why use Lucidant Polymers for microarray surface chemistry?

Our continuous commitment to quality makes Lucidant a leader in the custom-chemistry industry. As experts in the synthesis of these copolymers for nearly a decade, Lucidant has a trusted relationship with the inventor of the MCP copolymer class. An ISO-9001:2015 accredited manufacturing laboratory in California, Lucidant satisfies customers around the globe. Our customers include major international companies and prestigious academic institutions, renowned for their innovation and product offerings. Our customers either have developed, or are in-development of, biomarker analysis and microarray systems using our MCP-class copolymers as components.

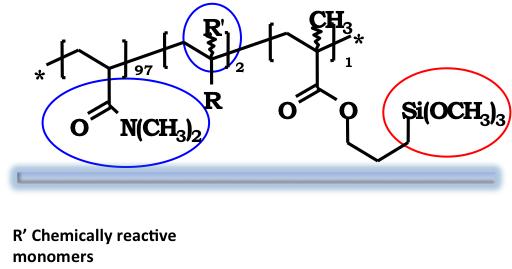

How do these copolymers work?

Lucidant’s MCP family of microarray copolymers combines specialized monomers to create an end molecule, which can bind a target analyte to an immobilizing surface. Copolymers can be modified through clever chemistry to preferentially capture certain targets over others.

The MCP copolymer is easily and readily coated onto a slide (or other surface), then dried; coated slides are very stable once dry.

In the next phase, a target-containing solution is spotted onto the array. Target molecules bind with the probe. Once binding is complete, the surface is then ready for analysis.

What about selective binding for other functional groups?

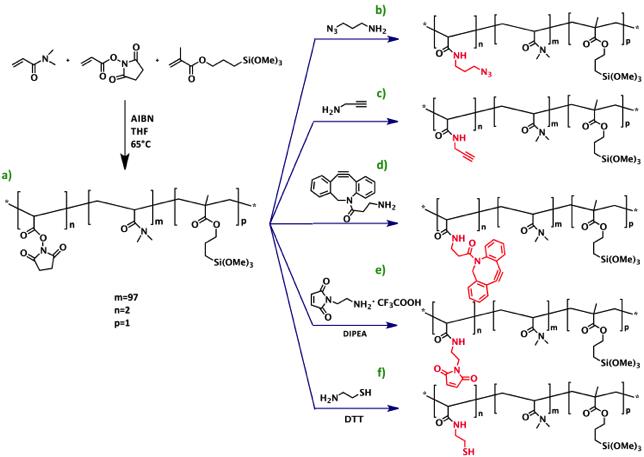

Lucidant is developing a next-generation lineup of copolymers for optimized binding: azide, maleimide, DBCO, and thiols, and has early designs available in limited amounts for inquiry. All copolymers in development are for research use only.

What should I consider when choosing a surface? (1)

- High binding capacity

- Ability to retain protein activity

- Low variability between slides

- High signal-to-noise ratios

- Stability to environmental changes

- Low cost, robust, easily prepared

- Minimal nonspecific adsorption

References are adapted from the following articles:

- High sensitivity protein assays on microarray slides” Cretich, Chiari et al (2019)

- Direct Observation of conformation of a Polymeric Coating with Implications in Microarray Applications” Yalcin, Unlu et al (2009).

- Allergen microarrays on high-sensitivity silicon slides” Cretich, Chiara et al (2010)

- Synthesis of Clickable coating Polymers by Postpolymerization Modification: Applications in Microarray Technology” Sola, Chiari et al (2016)

- Lucidant offers you a reliable manufacturer for our family of novel coating polymers.

- All products are made-to-order in our state of the art production lab.

- Alongside our Research and Design team, our process is continually improving.

- All design and processes within Lucidant Polymers stand up to, or exceed, the rigors of ISO-9001:2015 standards.

Microarray Coatings

Lucidant Coating Polymers

Lucidant offers a wide range of functional polymers that allow to coat slides of different materials for DNA and protein microarray. The coating procedure is fast, simple, and can be performed in any laboratory. Link to the procedure. The use of polymeric materials for modifying/functionalizing substrates is one of the most effective ways for tailoring surface characteristics.

Characteristics of the surface coating:

- The surface exhibits functional groups for the easy immobilization of molecules of interest;

- The binding between the biomolecule and the solid surface is strong enough to retain the molecule on the surface during the entire biosensing experiment;

- The surface is inherently inert and resists non-specific adsorption;

- The coupling chemistry allows the control of biomolecule orientation;

- The local chemical environment allows the immobilized molecules to retain the native conformation and its functionality.

Polymer selection

All MCP polymers form a coating on the following materials: Glass, silicon oxide, silicon nitride, gold, PDMS, COC, and Teflon.

- MCP-2 is suitable for protein-arrays. Order here

- MCP-4 is recommended for DNA and peptide arrays. MCP-4 is the preferred coating for glass and silicon substrates. Order here

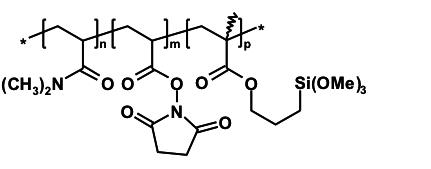

Chemical structure for MCP-2 and MCP-4

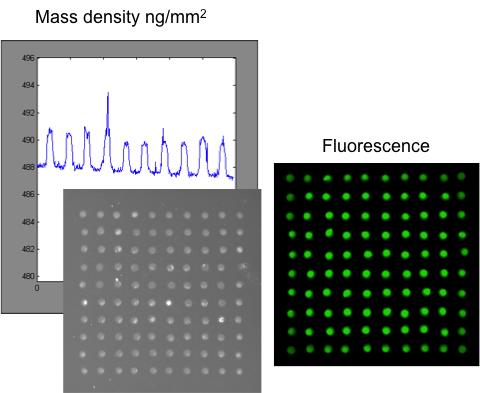

Immobilization of oligonucleotides on silicon oxide surface: (left) label free, interferometric image of surface spots, (right) fluorescence intensity after hybridization with CY3 labeled complementary oligonucleotide.

Polymers for spcecial coating applications:

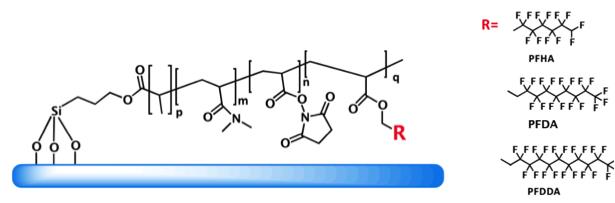

- MCP-2F is for the coating of hydrophobic surfaces. Order here

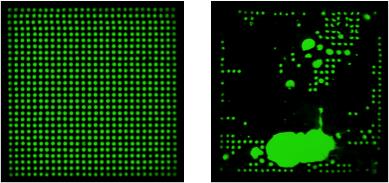

The lower surface energy of MCP-2F prevents spreading and merging of the spots

Spots on MCP-2F (pitch 160 microns) versus a standard spotting formulation at small pitch spacing of 160 microns on silicon substrate

- MCP-click are available with the following functional groups: azide, DBCO, and maleimide. They allow oriented immobilization of DNA. Contact us

- Video demonstration of MCP application Watch

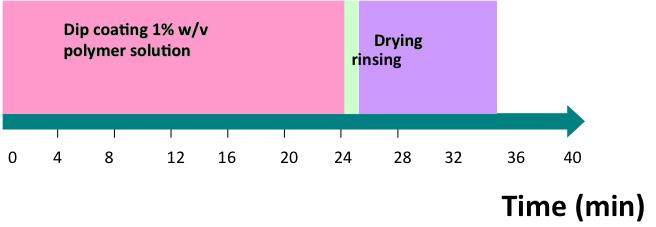

Procedure for Coating Microarray Slides with MCP-2(< 40 minute process)

Overview Lucidant coatings

We have prepared a summary of the scientific literature that cites the use of Lucidant microarray polymers. The publications have been categorized by the type of slide coating used, probes printed, and application. This is a useful guide when deciding which of the Lucidant polymers to use with any particular application.

Lucidant Coating Kits (MCP-2, -2F, -4, and others)

- 1 mL coating kit (including 1mL of MCP polymers, 250mL of Coating Solution, 250mL of Blocking Solution and 20mL of Spotting Solution) allows to coat at least 50 slides resulting in a cost for slide of $10.

- No need to worry about slide stability as one can prepare the exact amount of slides needed right before the sensing experiment.

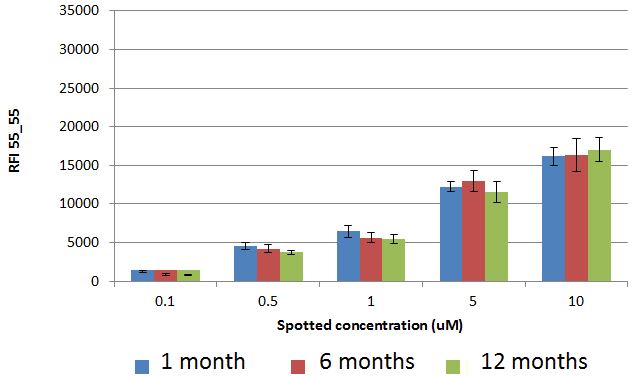

MCP polymer stability:1 year when properly stored at -20°C.

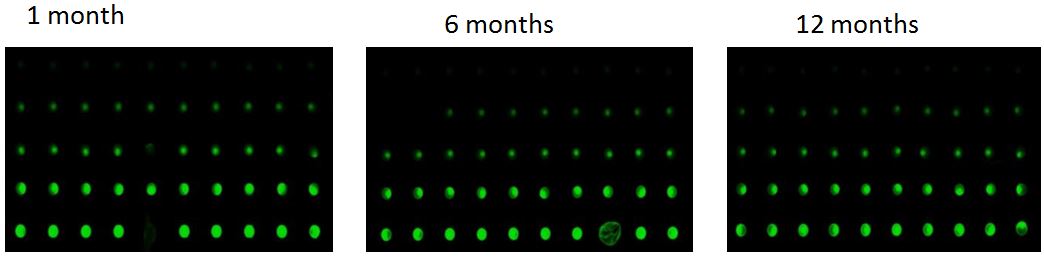

Images of the chips coated with MCP polymers stored at -20°C (Laser power and PTM gain 55_55% Scanner Perkin Elmer)

Spot Fluorescence intensity on chips coated with MCP polymers stored at -20°C for 1 month, 6 months and 12 months.

Lucidant Polymers to modulate EOF in capillary electrophoresis

Capillary electrophoresis (CE) is a powerful analytical technique that combines the advantages of electrophoretic separation with automation, allowing for a fast and efficient separation of a wide variety of compounds, including chemical, pharmaceutical and biological samples.

To obtain highly efficient and reproducible CE separations of proteins, peptides and DNA an effective modification of the surface of the capillary is necessary to:

- suppress, reduce or control electroosmotic flow

- prevent adsorption of proteins that causes peak broadening and loss of separation efficiency

- achieve reproducibility and low background noise in CE coupled to mass spectrometry (MS)

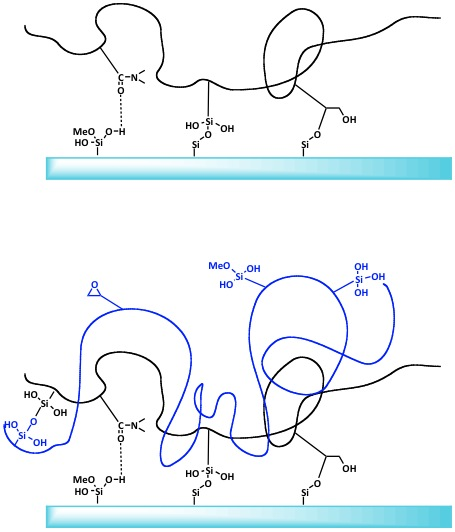

CE coatings must withstand shear forces and competition with various species present in the running buffer (urea, detergents and proteins). Therefore, methods that provide stable interfaces, even under harsh conditions, are generally preferred. Lucidant has introduced a family of polymers that allows to form a covalent coating on the capillary wall by a process that conjugates physi- and chemisorption.

Lucidant MCP-3 is a copolymer of N,N-dimethylacrylamide (DMA), N- and 3-(trimethoxysilyl) propyl methacrylate (MAPS) bearing epoxy groups. By a fully authomated protocol this polymer Link to the protocol, sold as powder, forms a stable coating in 3hours.

Schematic representation of MCP-3 coating

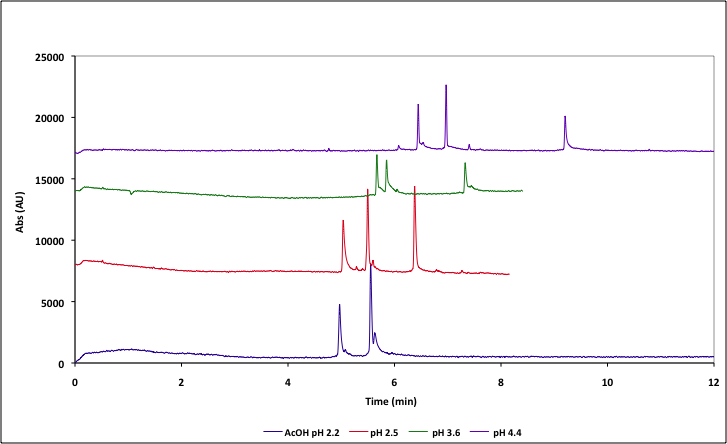

MCP-3 Lucidant polymer coatings suppresses EOF to a negligile value

Separation of alkaline proteins in MCP-3 coated capillary

Experimental conditions:

Capillary L=54 cm ID= 50

Coating online with MCP-3

EOF pH 8.5= 3 x 10-11 m2/Vsec

EOF pH 2.2 AcOH = -2 x 10-10 m2/Vsec

Alkaline mix: lysozime, cytochrome C, ribonuclease A 1 mg/mL in DI water

Injection 0.3 psi 2 sec

Separation 30 kV

Running buffers:

- pH 2.2 AcOH

- pH 2.5 NaH2PO4/NaOH

- pH 3.6 Formic Acid/NaOH

- pH 4.4 6-EACA-AcOH

Separation of alkaline proteins in MCP-3 coated capillaries

Polyacrylamides

Polyacrylamides, gels, and acrylamide monomers

Lucidant's core technical expertise is polyacrylamide chemistry for electrophororetic applications. Our specialized manfacturing process allows synthesis of polymers with targeted, precisely controlled molecular weights up to a massive 25MDa. Lucidant can synthesize linear or cross-linked polyacrylamides to customer specs. Material can be supplied as bulk powder or as a ready-to-use gel.Order here

In addition, Lucidant can provide novel acrylamide monomers that enhance the stability, separation properties, or hydrophobicity of polyacrylamide gels. If you have an existing need or a novel application, please contact us with your requirements.